- Services

- All Services

- All Locations

- Surveying

- Drone Infrastructure Services

- Drone Services for Agriculture

- Drone Inspection for Cell Towers

- Drone Media Services

- Drone Mapping Services

- Drone Mining Inspection

- Drone for Surveillance And Security

- Industrial Robotics and Unmanned Systems

- Semiconductor Design and Innovation Services

- Factory Automation Solutions

- Portfolio

- Unmanned Products

- Drone Training

- Blog

- Brochure

- Contact us

- Services

- All Services

- All Locations

- Surveying

- Drone Infrastructure Services

- Drone Services for Agriculture

- Drone Inspection for Cell Towers

- Drone Media Services

- Drone Mapping Services

- Drone Mining Inspection

- Drone for Surveillance And Security

- Industrial Robotics and Unmanned Systems

- Semiconductor Design and Innovation Services

- Factory Automation Solutions

- Portfolio

- Unmanned Products

- Drone Training

- Blog

- Brochure

- Contact us

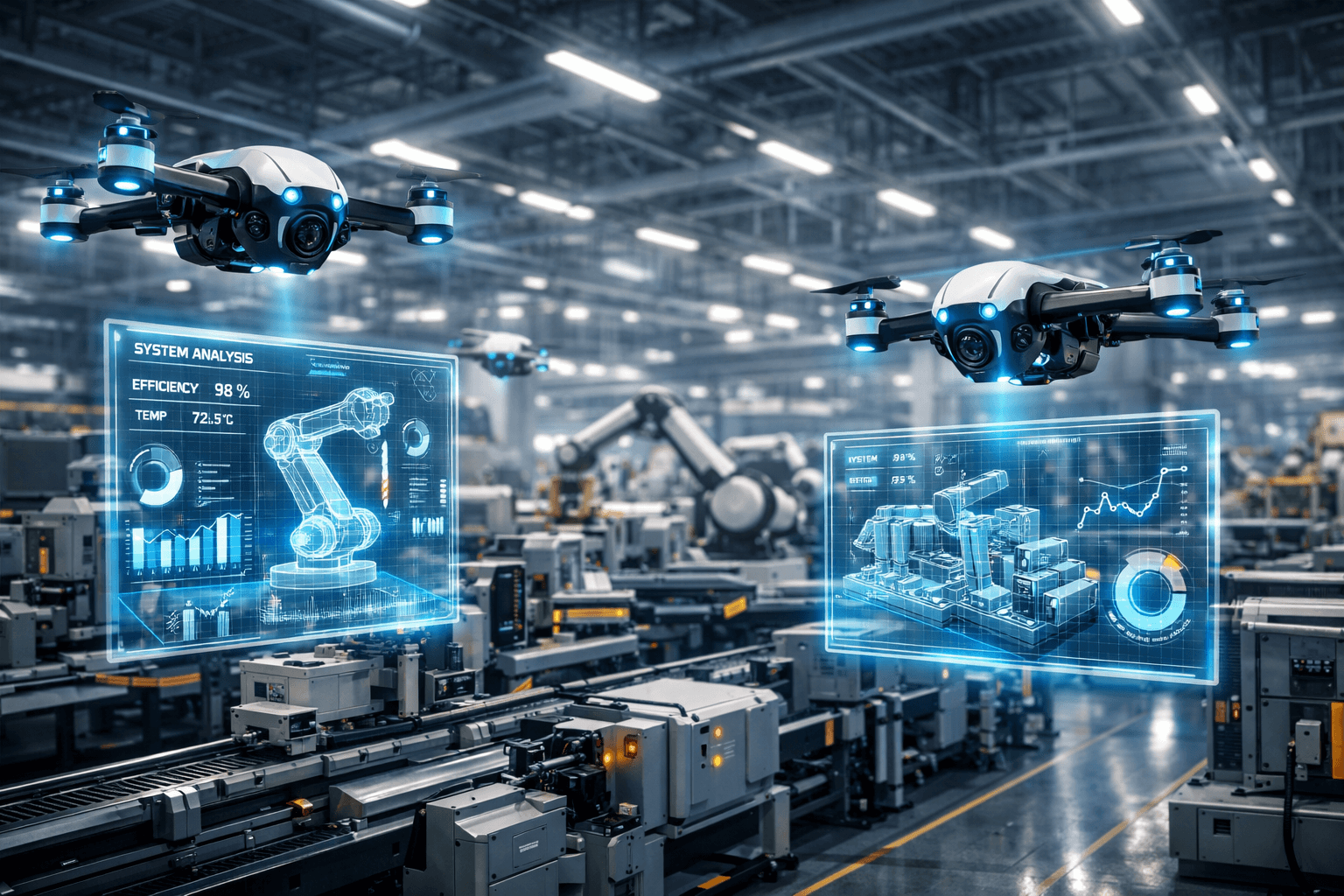

How AI Drones Enable Digital Twins in Manufacturing Plants

In the era of Industry 4.0, smart factories are leveraging AI drones to gather real-time data and enhance operational efficiency. One of the most transformative applications of this technology is creating digital twins—virtual replicas of physical assets and processes that enable manufacturers to simulate, monitor, and optimize factory operations.

By integrating AI drones with computer vision and IoT systems, manufacturers can collect precise spatial and visual data without disrupting production. This allows them to build accurate digital twins that reflect the current state of equipment, machinery, and even entire factory layouts.

1. AI Drones Capture Accurate Data for Digital Twins

Creating a digital twin requires high-resolution, accurate data about the factory environment. AI drones can fly autonomously across manufacturing plants, capturing images, videos, and sensor readings from hard-to-reach areas.

This data includes details about machinery, pipelines, storage areas, and workspaces. Using computer vision algorithms, AI drones detect subtle changes, identify wear and tear, and provide real-time updates, which are essential for a reliable digital twin.

2. AI Drones Enable Real-Time Monitoring

Digital twins are only valuable if they reflect the current state of physical assets. AI drones continuously scan the factory floor, monitoring machinery, production lines, and infrastructure.

The real-time data feeds into the digital twin, allowing managers to track equipment performance, detect anomalies, and respond to potential issues before they cause downtime. This continuous monitoring ensures smarter, more responsive manufacturing operations.

3. Optimizing Processes with AI Drones

With accurate digital twins created from AI drones, factories can simulate production workflows and test changes without disrupting real operations.

For example, managers can rearrange assembly lines, evaluate space utilization, or optimize robot movements virtually. AI drones provide the precise measurements and visual data required to make these simulations effective, enabling cost-efficient and risk-free optimization.

4. Enhancing Maintenance and Safety

AI drones integrated with digital twins also improve maintenance and safety strategies. Thermal cameras and other sensors on drones detect overheating equipment, leaks, or structural weaknesses.

This data updates the digital twin, allowing predictive maintenance and risk assessment in a virtual environment. As a result, factories can reduce unexpected failures, improve worker safety, and extend the lifespan of machinery.

5. Supporting Decision-Making in Smart Factories

Digital twins powered by AI drones provide actionable insights for decision-makers. Managers can analyze data trends, simulate “what-if” scenarios, and predict production outcomes.

By combining AI drone data with analytics software, manufacturers gain a holistic view of their operations. This enables faster decisions, better resource allocation, and more efficient processes across the factory.

Conclusion: The Future of Digital Twins with AI Drones

AI drones are transforming how digital twins are created and used in manufacturing plants. From accurate data capture and real-time monitoring to process optimization and predictive maintenance, these drones are making factories smarter, safer, and more efficient.

As smart factories continue to evolve, integrating AI drones into digital twin strategies will become an essential part of Industry 4.0, driving innovation and competitiveness in the manufacturing sector.